Where Is BMW Made? Exploring BMW’s Global Manufacturing Network

BMW vehicles are manufactured at several locations worldwide. While BMW is headquartered in Munich, Germany, production facilities are also located in the United States, China, Mexico, South Africa, and the United Kingdom, among other countries.

Have you ever wondered where BMW cars come from? Many people admire BMWs for their sleek design and powerful engines. But it’s fascinating to think about the journey these cars take before they reach our roads.

When you ask, “Where is BMW made?”, you might be surprised to learn there’s more to it than just one place. BMW has factories in several countries, each with its unique touch. Did you know that they even produce some models right here in the United States?

Imagine watching a BMW being built. Workers carefully put together each piece with pride. Each car tells a story of teamwork and expertise. This makes you wonder: how did BMW become such a well-known name worldwide? In this article, we will explore the fascinating world of BMW production.

Where Is BMW Made: Complete Global Overview

BMW vehicles are manufactured in 12 countries across 31 production facilities worldwide as of 2024. The company’s global manufacturing network produces over 2.5 million vehicles annually and employs more than 140,000 people in manufacturing operations alone.

Primary Manufacturing Countries:

- Germany – 10 facilities (headquarters and largest production base)

- United States – 1 major facility (Spartanburg, South Carolina)

- China – 3 facilities (joint venture with Brilliance)

- United Kingdom – 3 facilities (primarily MINI production)

- Mexico – 1 facility (newest, opened 2024)

- India – 1 facility (Chennai)

- South Africa – 1 facility (Rosslyn)

- Brazil – 1 facility (Araquari)

- Austria – 1 facility (Steyr – engines)

- Thailand – 1 facility (Rayong)

- Malaysia – 1 facility (Kulim)

- Egypt – 1 facility (6th of October City)

This distributed manufacturing approach allows BMW to:

- Reduce transportation costs and delivery times

- Avoid import tariffs in key markets

- Adapt production to local preferences

- Maintain supply chain flexibility

- Support local economies and employment

BMW’s German Manufacturing Heritage and Current Operations

Headquarters and Main Production: Munich

BMW Group Plant Munich remains the spiritual and operational heart of BMW manufacturing, established in 1922 and continuously expanded over the past century.

| Facility Details | Specifications |

|---|---|

| Established | 1922 |

| Employees | 9,000+ |

| Annual Capacity | 340,000 vehicles |

| Primary Models | 3 Series, 4 Series, M3, M4 |

| Facility Size | 5.4 million square feet |

| Special Features | BMW Welt visitor center, Museum |

Current Production at Munich:

- BMW 3 Series (G20) – All variants including plug-in hybrid

- BMW 4 Series (G22/G23) – Coupe and Convertible

- BMW M3 (G80) – High-performance sedan

- BMW M4 (G82/G83) – High-performance coupe and convertible

- BMW i4 (G26) – Electric sedan (since 2021)

BMW Plant Dingolfing: The Largest BMW Facility

BMW Plant Dingolfing is BMW’s largest production facility globally, specializing in luxury and electric vehicles.

| Facility Details | Specifications |

|---|---|

| Established | 1973 |

| Employees | 18,000+ |

| Annual Capacity | 370,000 vehicles |

| Primary Models | 5 Series, 7 Series, 8 Series, iX, i7 |

| Facility Size | 6.2 million square feet |

| Investment (2020-2025) | €1.7 billion |

Current Production at Dingolfing:

- BMW 5 Series (G30/G31) – Sedan and Touring

- BMW 7 Series (G70) – Luxury flagship sedan

- BMW 8 Series (G14/G15/G16) – Coupe, Convertible, Gran Coupe

- BMW iX (I20) – Electric luxury SUV

- BMW i7 (G70) – Electric luxury sedan

- BMW XM (G09) – M-division luxury SUV

BMW Plant Regensburg: Compact and Mid-Size Specialists

BMW Plant Regensburg focuses on BMW’s entry-level and compact vehicle production.

| Facility Details | Specifications |

|---|---|

| Established | 1986 |

| Employees | 10,000+ |

| Annual Capacity | 340,000 vehicles |

| Primary Models | 1 Series, 2 Series |

| Recent Investment | €750 million (2020-2023) |

Other German BMW Facilities

BMW Plant Leipzig (Established 2005)

- Annual Capacity: 340,000 vehicles

- Primary Models: 2 Series Active Tourer, i3 (discontinued), iX1

- Employees: 5,500+

- Special Feature: Wind-powered, carbon-neutral facility

BMW Plant Landshut (Established 1967)

- Specialization: Component manufacturing

- Focus: Chassis components, suspension systems

- Employees: 3,500+

BMW Plant Berlin (Established 1969)

- Specialization: Motorcycle production

- Models: All BMW Motorrad motorcycles for Europe

- Annual Capacity: 200,000+ motorcycles

North American Production Facilities

BMW Manufacturing Co. Spartanburg, South Carolina

BMW Plant Spartanburg is BMW’s largest production facility outside Germany and the global production center for BMW X models.

| Facility Details | Specifications |

|---|---|

| Established | 1994 |

| Employees | 11,000+ |

| Annual Capacity | 450,000 vehicles |

| Facility Size | 8 million square feet |

| Total Investment | $12+ billion (1994-2024) |

| Land Area | 1,150 acres |

Current Production at Spartanburg:

- BMW X3 (G01) – Compact luxury SUV

- BMW X4 (G02) – Coupe-style SUV

- BMW X5 (G05) – Mid-size luxury SUV

- BMW X6 (G06) – Coupe-style luxury SUV

- BMW X7 (G07) – Full-size luxury SUV

- BMW XM (G09) – M-division luxury SUV (shared with Dingolfing)

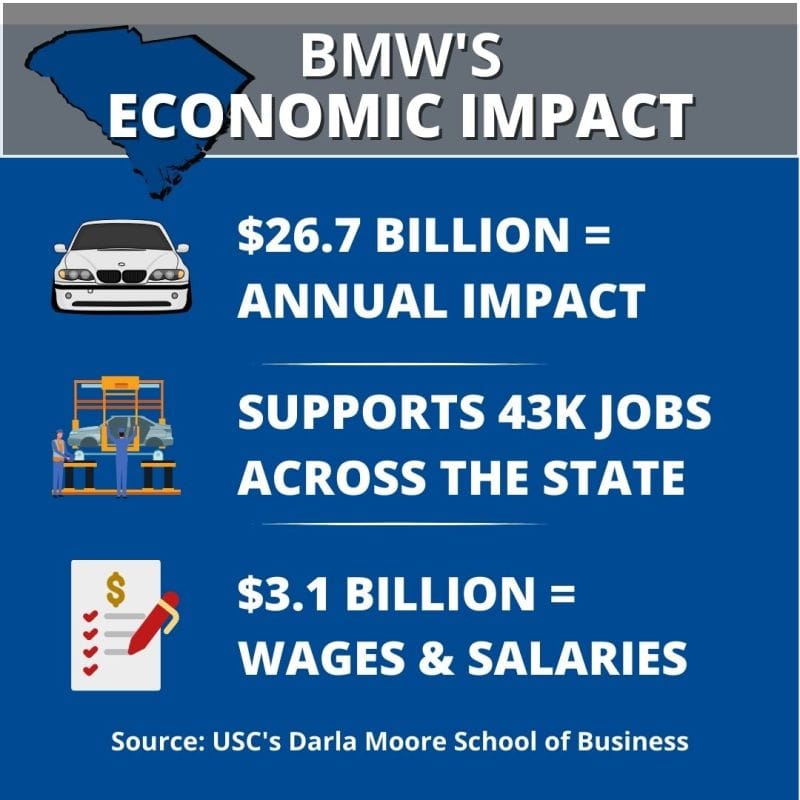

Economic Impact:

- Largest BMW manufacturing facility by production volume

- Largest automotive exporter in the United States

- Exports to over 125 countries worldwide

- Contributed over $8 billion to the U.S. economy (2020-2023)

BMW Plant San Luis Potosí, Mexico (New 2024)

BMW’s newest production facility began operations in early 2024, representing a $1 billion investment in North American manufacturing capacity.

| Facility Details | Specifications |

|---|---|

| Opened | 2024 |

| Employees | 1,500+ (expanding to 2,500) |

| Annual Capacity | 175,000 vehicles (Phase 1) |

| Primary Models | 3 Series (for Americas market) |

| Investment | $1 billion |

| Facility Size | 2.4 million square feet |

Asian Manufacturing Network

BMW Brilliance Automotive (China)

BMW operates three major facilities in China through its joint venture with Brilliance Automotive, serving the world’s largest automotive market.

BMW Plant Dadong (Shenyang)

| Facility Details | Specifications |

|---|---|

| Established | 2003 |

| Employees | 5,000+ |

| Annual Capacity | 400,000 vehicles |

| Primary Models | 5 Series Li, X1, iX1 |

| Recent Investment | $3.6 billion (2018-2023) |

BMW Plant Tiexi (Shenyang)

| Facility Details | Specifications |

|---|---|

| Established | 2012 |

| Employees | 4,000+ |

| Annual Capacity | 300,000 vehicles |

| Primary Models | X2, 2 Series Active Tourer |

BMW Plant Lydia (Shenyang) – New 2022

| Facility Details | Specifications |

|---|---|

| Opened | 2022 |

| Annual Capacity | 300,000 vehicles |

| Primary Models | iX3, i3 (China-specific), upcoming iX models |

| Investment | $2.24 billion |

| Special Feature | BMW’s most advanced electric vehicle facility |

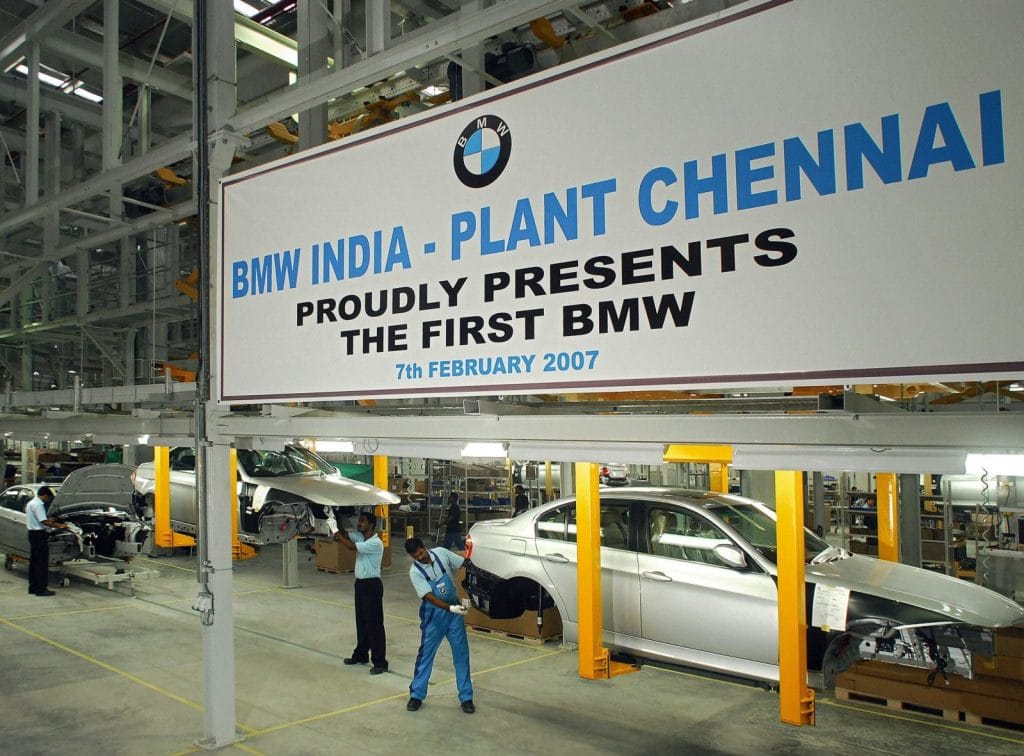

BMW Plant Chennai, India

BMW Plant Chennai serves as BMW’s production hub for the Indian subcontinent and export markets.

| Facility Details | Specifications |

|---|---|

| Established | 2007 |

| Employees | 1,000+ |

| Annual Capacity | 25,000 vehicles |

| Primary Models | 2 Series Gran Coupe, 3 Series, X1 |

| Market Served | India, ASEAN countries |

| Investment | $170 million |

BMW Plant Rayong, Thailand

| Facility Details | Specifications |

|---|---|

| Established | 2000 |

| Primary Function | Assembly and distribution hub |

| Annual Capacity | 20,000 vehicles |

| Market Served | Thailand, ASEAN region |

| Models | 3 Series, 5 Series, X3, X5 (CKD assembly) |

BMW Plant Kulim, Malaysia

| Facility Details | Specifications |

|---|---|

| Established | 2003 |

| Annual Capacity | 14,000 vehicles |

| Primary Function | CKD assembly |

| Market Served | Malaysia, regional export |

European Production Beyond Germany

MINI Production in the United Kingdom

BMW Plant Oxford – The home of MINI production since BMW acquired the brand in 2000.

| Facility Details | Specifications |

|---|---|

| BMW Ownership Since | 2000 |

| Employees | 4,500+ |

| Annual Capacity | 240,000 vehicles |

| Primary Models | MINI Cooper, MINI Electric |

| Historical Note | Original home of MINI since 1959 |

MINI Plant Swindon – Body panel production for MINI vehicles MINI Plant Hams Hall – Engine production for MINI and BMW vehicles

BMW Motorrad Production

BMW Plant Berlin – European motorcycle headquarters

- All BMW motorcycles for the European market

- R&D center for future motorcycle technologies

- Annual capacity: 200,000+ motorcycles

African and South American Operations

BMW Plant Rosslyn, South Africa

BMW’s African production hub serves the continent and export markets.

| Facility Details | Specifications |

|---|---|

| Established | 1973 |

| Employees | 1,500+ |

| Annual Capacity | 76,000 vehicles |

| Primary Models | 3 Series (for African and export markets) |

| Market Served | Africa, Middle East, Asia-Pacific |

| Investment (2018-2022) | $77 million |

BMW Plant Araquari, Brazil

| Facility Details | Specifications |

|---|---|

| Established | 2014 |

| Annual Capacity | 32,000 vehicles |

| Primary Models | X1, X3 (for South American markets) |

| Employees | 1,300+ |

| Market Served | Brazil, South America |

BMW Plant 6th of October City, Egypt

| Facility Details | Specifications |

|---|---|

| Established | 1999 |

| Primary Function | CKD assembly |

| Annual Capacity | 6,000 vehicles |

| Market Served | Egypt, North Africa |

| Models | 3 Series, 5 Series, X1, X3 |

Component and Engine Manufacturing Locations

Engine Production Centers

BMW Plant Steyr, Austria

| Specialization | Details |

|---|---|

| Primary Focus | Diesel engines, gasoline engines |

| Established | 1979 |

| Annual Capacity | 980,000 engines |

| Key Products | TwinPower Turbo engines, 6-cylinder diesels |

| Employees | 4,500+ |

BMW Plant Hams Hall, UK

| Specialization | Details |

|---|---|

| Primary Focus | Small gasoline engines |

| Annual Capacity | 500,000 engines |

| Key Products | 3-cylinder and 4-cylinder TwinPower Turbo engines |

| Serves | MINI and BMW 1/2 Series |

Battery and Electric Component Production

BMW Battery Production Locations:

- Dingolfing, Germany – High-voltage batteries for iX and i7

- Spartanburg, USA – Battery assembly for X models

- Shenyang, China – Battery production for Chinese market EVs

Historical Timeline of BMW Global Expansion

Phase 1: German Foundation (1916-1960s)

- 1916: BMW was founded in Munich

- 1922: First automobile production begins

- 1929: BMW acquires Eisenach facility

- Post-WWII: Rebuilding German operations

Phase 2: International Expansion Begins (1970s-1990s)

- 1973: BMW Plant Dingolfing opens (first major expansion)

- 1973: BMW Plant Rosslyn, South Africa, established

- 1986: BMW Plant Regensburg opens

- 1994: BMW Plant Spartanburg, USA, begins production

Phase 3: Global Network Development (2000s-2010s)

- 2000: BMW acquires MINI, gains UK production

- 2003: BMW Plant Dadong, China, begins operations

- 2005: BMW Plant Leipzig opens

- 2007: BMW Plant Chennai, India, established

- 2012: BMW Plant Tiexi, China, opens

- 2014: BMW Plant Araquari, Brazil, begins production

Phase 4: Electric Future and Recent Expansion (2020s-Present)

- 2022: BMW Plant Lydia, China opens (EV focus)

- 2024: BMW Plant San Luis Potosí, Mexico, begins production

- 2025: Planned expansions in China and Europe for EV production

Future Manufacturing Plans and Expansions (2024-2030)

Confirmed New Facilities and Expansions

BMW Plant Debrecen, Hungary (Opening 2025)

| Project Details | Specifications |

|---|---|

| Opening | 2025 |

| Investment | €1 billion |

| Annual Capacity | 150,000 vehicles |

| Focus | Electric vehicles (Neue Klasse platform) |

| Employees | 1,000+ |

BMW iX Production Expansion

- Dingolfing: Additional €400 million investment for expanded iX production

- Spartanburg: Preparing for iX production for the North American market

Neue Klasse Platform Manufacturing

BMW’s revolutionary Neue Klasse electric platform will be produced at:

- Debrecen, Hungary (2025) – Primary European production

- San Luis Potosí, Mexico (2027) – Americas production

- Shenyang, China (2026) – Asian market production

Sustainability and Manufacturing Goals

BMW’s 2030 Manufacturing Targets:

- 50% reduction in CO2 emissions per vehicle produced

- 100% renewable energy at all facilities

- Circular economy principles in manufacturing

- Zero waste to landfill across all facilities

Supply Chain and Global Sourcing Strategy

Raw Materials Sourcing

Key Material Origins:

- Aluminum: Australia, Canada, Russia

- Steel: Germany, USA, China (regional sourcing)

- Lithium: Chile, Australia, China

- Cobalt: Democratic Republic of Congo, Australia

- Rare Earth Elements: China, USA, Australia

- Leather: Germany, USA, Brazil

- Electronics: Germany, China, South Korea

Supplier Network Statistics

| Supply Chain Metrics | Numbers |

|---|---|

| Global Suppliers | 12,000+ companies |

| Tier 1 Suppliers | 1,200+ companies |

| Countries with Suppliers | 70+ countries |

| Annual Procurement Volume | €60+ billion |

| Supplier Diversity Programs | 45+ countries |

Supply Chain Resilience Strategies

Following disruptions from 2020-2022, BMW has implemented:

- Dual Sourcing: Multiple suppliers for critical components

- Regional Supply Chains: Reduced dependence on long-distance shipping

- Strategic Inventory: Higher safety stock for critical components

- Supplier Development: Investment in supplier capability and capacity

- Digital Supply Chain: Real-time visibility and predictive analytics

Economic Impact of BMW Manufacturing

Global Employment Impact

Direct BMW Manufacturing Employment:

| Region | Employees | Major Locations |

|---|---|---|

| Germany | 85,000+ | Munich, Dingolfing, Regensburg, Leipzig |

| North America | 12,500+ | Spartanburg, San Luis Potosí |

| China | 15,000+ | Shenyang facilities |

| United Kingdom | 5,000+ | Oxford, Swindon, Hams Hall |

| Other Regions | 8,000+ | India, South Africa, Brazil, etc. |

| Total Global | 140,000+ | 31 facilities worldwide |

Economic Multiplier Effects

BMW’s manufacturing operations generate estimated economic multiplier effects:

- Germany: €12 billion annual economic impact

- United States: $8 billion annual economic impact (primarily South Carolina)

- China: $6 billion annual economic impact

- United Kingdom: $2.5 billion annual economic impact

Tax and Investment Contributions

Recent Major Investments (2020-2025):

| Location | Investment Amount | Purpose |

|---|---|---|

| Dingolfing, Germany | €1.7 billion | Electric vehicle expansion |

| Spartanburg, USA | $1.7 billion | X model expansion |

| Shenyang, China | $3.6 billion | New Lydia plant and expansions |

| San Luis Potosí, Mexico | $1 billion | New facility |

| Debrecen, Hungary | €1 billion | New electric vehicle facility |

| Global Total | €15+ billion | Manufacturing expansion |

Research and Development Integration

Manufacturing R&D Centers

BMW’s manufacturing innovation centers:

- BMW Group TechOffice Munich – Digital manufacturing

- BMW Manufacturing Lab, Spartanburg – Industry 4.0 technologies

- BMW China Technology Center – Local adaptation and innovation

- BMW Group UK Technology Hub – Electrification research

Advanced Manufacturing Technologies

Current Technology Implementations:

- Industry 4.0 Integration: IoT sensors, AI-driven quality control

- Robotics and Automation: Collaborative robots (cobots) for precision assembly

- Additive Manufacturing: 3D printing for prototyping and small-batch production

- Digital Twin Technology: Virtual factory simulation and optimization

- Augmented Reality: AR-assisted assembly and quality inspection

Environmental and Sustainability Initiatives

Carbon Neutral Manufacturing Goals

BMW’s Path to Carbon Neutrality:

- 2025 Target: 80% reduction in CO2 emissions per vehicle (vs. 2019)

- 2030 Target: Carbon-neutral manufacturing at all facilities

- Renewable Energy: 90% of global manufacturing powered by renewables (2024)

Circular Economy in Manufacturing

Material Recovery and Recycling:

- Steel Recycling: 95% of production steel waste is recycled

- Aluminum Recovery: 99% of aluminum shavings reused

- Water Management: Closed-loop water systems reduce consumption by 70%

- Waste Reduction: Zero waste to landfill achieved at 15+ facilities

Sustainable Material Innovation

BMW’s sustainable material initiatives:

- Bio-based Materials: Natural fiber composites, renewable plastics

- Recycled Materials: Up to 50% recycled content in new vehicles

- Responsible Sourcing: Blockchain tracking for raw materials

- Closed-Loop Systems: Component remanufacturing programs

Quality Control and Manufacturing Standards

BMW Production System (BPS)

BMW’s proprietary production methodology ensures consistent quality across all global facilities:

Core BPS Principles:

- Standardization: Identical processes across all facilities

- Continuous Improvement: Kaizen methodology implementation

- Employee Empowerment: Quality responsibility at every level

- Technology Integration: Digital quality monitoring systems

Global Quality Metrics

BMW Manufacturing Quality Standards:

| Quality Metric | Target | Achievement (2023) |

|---|---|---|

| Defects per Million | <50 | 31 |

| First-Time Quality | >99.5% | 99.7% |

| Customer Satisfaction | >95% | 97.2% |

| Warranty Claims | <1% | 0.7% |

Certification and Standards

Global Manufacturing Certifications:

- ISO 9001: Quality management systems (all facilities)

- ISO 14001: Environmental management systems (all facilities)

- ISO 50001: Energy management systems (26 facilities)

- OHSAS 18001: Occupational health and safety (all facilities)

Conclusion

The answer to “Where is BMW made?” reveals a sophisticated global manufacturing network that spans 12 countries and 31 facilities, producing over 2.5 million vehicles annually. From BMW’s historic birthplace in Munich to cutting-edge electric vehicle facilities in China and Hungary, the company has evolved from a single German manufacturer into a truly global automotive producer.

FAQ

Where Are Most BMW Cars Made?

Germany remains BMW’s largest manufacturing base, producing approximately 40% of all BMW vehicles globally. The primary German facilities in Munich, Dingolfing, Regensburg, and Leipzig collectively produce over 1 million vehicles annually. However, for specific models like X series SUVs, the majority are manufactured at BMW’s Spartanburg, South Carolina, facility, which is the largest BMW plant by production volume outside Germany.

Are BMWs Made in America or German Cars?

BMW manufactured in the United States at the Spartanburg, South Carolina plant are built to identical specifications and quality standards as German-produced BMWs. The facility uses the same BMW Production System, identical parts and materials, and maintains the same quality certifications. Many Spartanburg-produced BMWs are exported globally, including back to Europe, demonstrating their equivalent quality and manufacturing standards.

What BMW Models Are Made in Each Country?

Germany: 3 Series, 4 Series, 5 Series, 7 Series, 8 Series, i4, iX, i7, 1 Series, 2 Series United States: X3, X4, X5, X6, X7, XM China: 1 Series, 2 Series Active Tourer, 5 Series Li, X1, X2, iX1, iX3 United Kingdom: All MINI models, MINI Electric Mexico: 3 Series (for Americas market) India: 2 Series Gran Coupe, 3 Series, X1 (for regional markets) South Africa: 3 Series (for African and export markets)

How Can I Tell Where My BMW Was Made?

You can determine where your BMW was manufactured by checking the Vehicle Identification Number (VIN). The first character indicates the manufacturing country: ‘W’ indicates Germany, ‘4’ or ‘5’ indicates the United States, ‘L’ indicates China, ‘S’ indicates the United Kingdom, and so on. You can also find manufacturing location information in your owner’s manual or by contacting BMW customer service with your VIN.

Does BMW’s Global Manufacturing Affect Quality?

BMW maintains identical quality standards across all manufacturing facilities through its BMW Production System (BPS). All facilities use the same processes, materials, suppliers, and quality control measures. Independent quality studies consistently show that BMW vehicles maintain equivalent quality ratings regardless of manufacturing location, with some facilities like Spartanburg receiving BMW’s highest quality awards.

Why Does BMW Manufacture Cars in Multiple Countries?

BMW’s global manufacturing strategy serves several purposes: reducing shipping costs and delivery times to regional markets, avoiding import tariffs and trade barriers, adapting production to local market preferences, maintaining supply chain flexibility during global disruptions, supporting local economies and employment, and optimizing production costs while maintaining quality standards.

What Is BMW’s Largest Manufacturing Facility?

By production volume, BMW Plant Spartanburg in South Carolina is BMW’s largest facility, producing over 450,000 vehicles annually. By facility size and employment, BMW Plant Dingolfing in Germany is the largest, employing over 18,000 people and specializing in luxury and electric vehicles. Both facilities represent significant investments and showcase BMW’s most advanced manufacturing technologies.

Are There Any BMW Models Made Exclusively in One Country?

Yes, several BMW models are produced exclusively at single locations: the BMW 7 Series and iX are made only in Dingolfing, Germany; all MINI models are produced exclusively in Oxford, UK; the BMW XM is made only in Dingolfing and Spartanburg; and Chinese-market-specific models like the 5 Series Li are produced only in China. This specialization allows BMW to optimize production efficiency and expertise for specific model lines.