How Do Ball Joints Work: A Comprehensive Guide

Ball joints play a critical role in your Ford F150’s suspension system, allowing the front wheels to move up and down while steering left and right. While these small components are often overlooked, they are crucial for both your vehicle’s handling and overall safety. In this guide, we’ll take an in-depth look at how ball joints work, their importance, and why maintaining them is key for your truck’s performance.

Key Takeaways

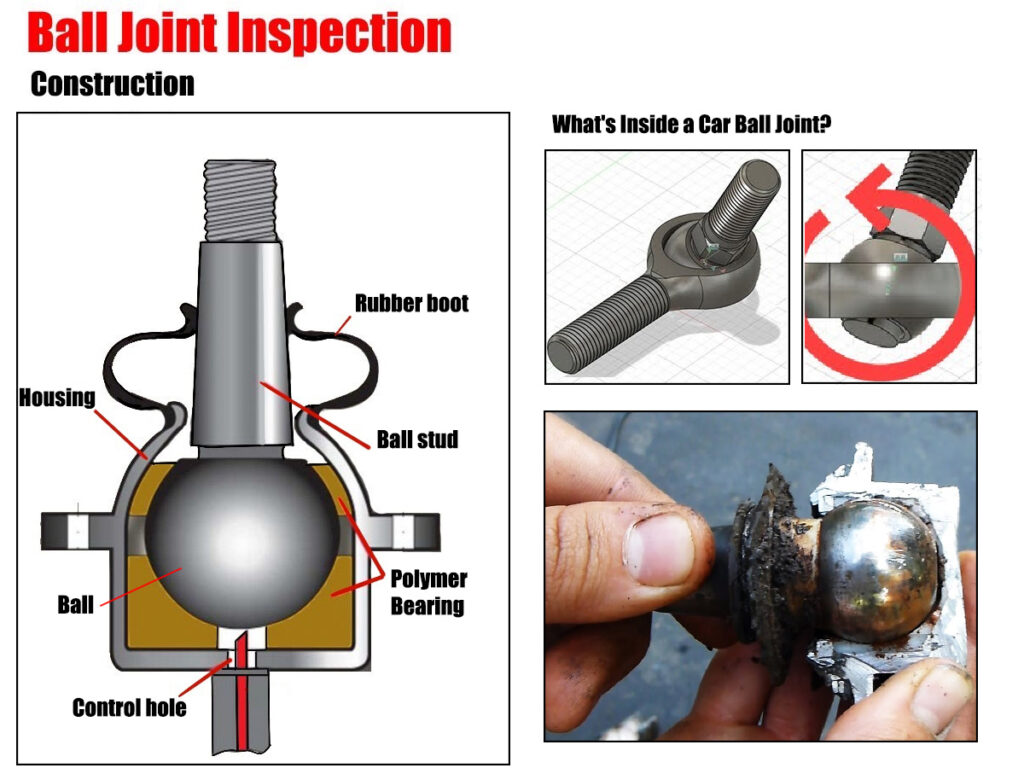

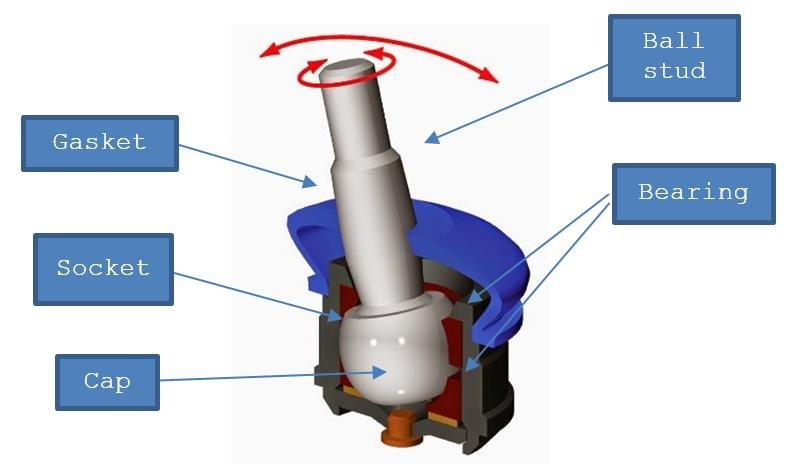

Ball joints are a key part of a vehicle’s suspension system that allow the wheels to move and steer while the suspension moves up and down. They work like a ball-and-socket joint, similar to the human hip, with a ball that fits into a socket:

How ball joints work Function Connect the control arms to the steering knuckles, allowing for smooth movement Location Part of the front suspension of most cars Types Upper ball joints are non-load bearing, while lower ball joints are usually load bearing Ball joints can wear out over time and need to be replaced. Signs of worn ball joints include: excessive vibration, rattling or clunking noises, irregular tire wear, and the vehicle pulling to one side.

What Are Ball Joints?

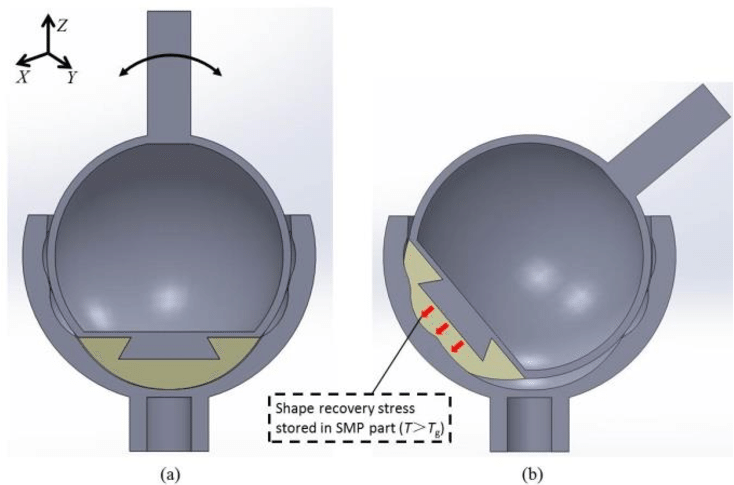

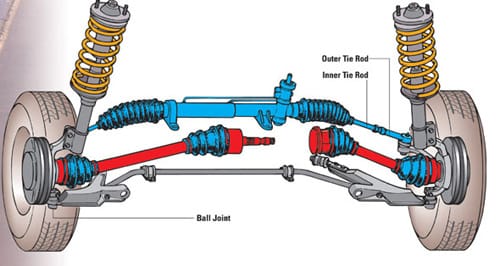

Ball joints are spherical bearings that connect the control arms to the steering knuckles, allowing for movement in multiple directions. They work similarly to a ball-and-socket joint in the human body, providing a wide range of motion. This flexibility allows your Ford F150 to absorb shocks from uneven roads and steer effectively.

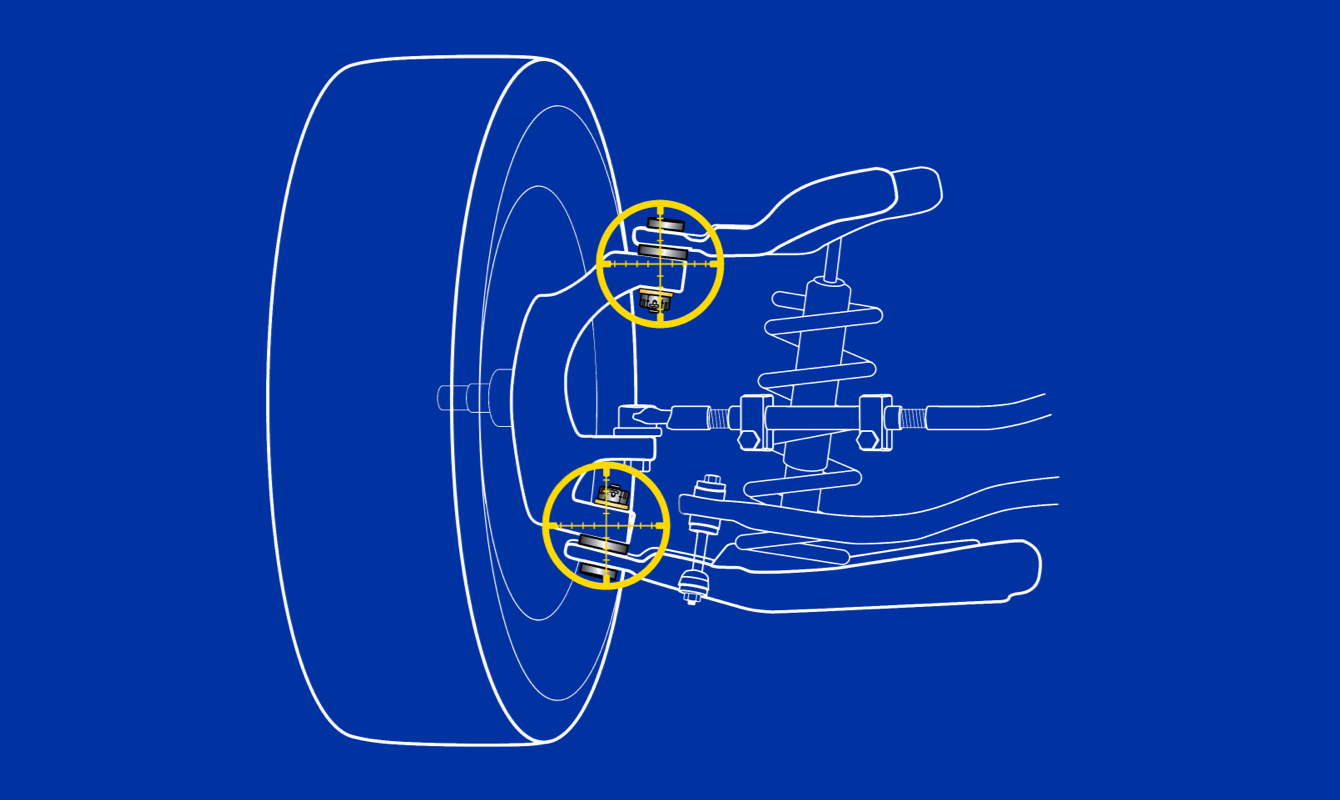

Ball joints are typically found in the front suspension, although some vehicles have them in the rear as well. They come in two types:

- Upper Ball Joints: Connect the upper control arm to the steering knuckle.

- Lower Ball Joints: Connect the lower control arm to the steering knuckle and bear most of the vehicle’s weight.

Both upper and lower ball joints are essential for smooth steering and suspension operation.

How Do Ball Joints Work?

Ball joints enable your vehicle’s suspension to pivot and flex while keeping the wheels aligned. When you drive over bumps or potholes, the suspension compresses and expands, but the ball joints allow the wheels to stay in contact with the road. Additionally, when you turn the steering wheel, the ball joints help the knuckles pivot, changing the direction of the wheels.

The ball inside the joint allows rotational movement in almost every direction, offering three degrees of freedom:

- Vertical Movement: As the vehicle moves up and down over bumps.

- Horizontal Movement: During steering when you turn the wheels left or right.

- Axial Rotation: The wheels also rotate as the suspension moves.

Without ball joints, steering and suspension would be rigid, and the vehicle would have a difficult time responding to road conditions, leading to poor handling and comfort.

Types of Ball Joints

Ball joints come in different configurations, depending on the vehicle’s suspension design. The most common types are:

- Load-Bearing Ball Joints: These are found in vehicles like the Ford F150, where the lower ball joints support most of the vehicle’s weight. They experience higher levels of stress and wear, so they tend to need replacement more frequently.

- Non-Load Bearing Ball Joints: These ball joints help with steering but don’t support the vehicle’s weight. In a typical F150 setup, the upper ball joints would be non-load bearing.

Signs of Worn Ball Joints

Given their constant use, ball joints do wear out over time. Some of the signs that your Ford F150’s ball joints might be failing include:

- Clunking or Popping Noises: You may hear clunking noises coming from the front suspension when driving over rough roads, especially when turning or hitting bumps.

- Vibrating Steering Wheel: A worn ball joint can cause the steering wheel to shake or vibrate, especially at higher speeds.

- Uneven Tire Wear: Ball joints that are loose or failing may cause the wheels to tilt slightly, resulting in uneven tire wear.

- Wandering Steering: If your steering feels loose or the vehicle tends to drift, it could be a sign of worn ball joints.

It’s crucial to replace worn ball joints as soon as possible to avoid further suspension damage or, worse, a catastrophic failure while driving.

How Long Do Ball Joints Last?

The lifespan of ball joints can vary widely depending on driving conditions, but on average, they can last between 70,000 to 150,000 miles. Off-road driving, carrying heavy loads, or frequent travel over rough terrain can shorten their lifespan.

Regular inspections are recommended, especially if you notice any signs of wear. If you’re unsure whether your ball joints need replacement, a qualified mechanic can perform a visual inspection and a physical test to check for excessive play or wear.

Can You Drive With Bad Ball Joints?

Driving with worn-out ball joints is not recommended. While it may be possible to drive short distances with minimal damage, failing ball joints can lead to a complete loss of control. In the worst-case scenario, a ball joint can break entirely, causing the wheel to collapse inward or outward, which is extremely dangerous.

If you suspect your ball joints are worn, it’s best to have them replaced immediately to avoid compromising your safety and your vehicle’s performance.

How to Maintain Ball Joints

Maintaining your ball joints is relatively simple and involves regular inspections and, if necessary, lubrication. Some ball joints come pre-sealed and don’t require lubrication, but others may need to be greased as part of routine maintenance.

- Inspect Regularly: During routine tire rotations or oil changes, ask your mechanic to inspect the ball joints for signs of wear.

- Lubricate: If your ball joints are greaseable, make sure they’re properly lubricated according to your Ford F150’s maintenance schedule.

- Replace When Necessary: Don’t wait too long to replace worn ball joints, as they directly affect the safety and handling of your vehicle.

Cost of Replacing Ball Joints

The cost to replace ball joints on a Ford F150 can vary depending on labor rates and the type of ball joint, but you can expect to pay between $200 to $400 for a single ball joint replacement. Keep in mind that if one ball joint is worn out, the others might not be far behind, so it’s often recommended to replace them in pairs.

Conclusion

Ball joints may be small, but they are a vital part of your Ford F150’s suspension system. They allow for smooth steering, help absorb shocks, and maintain proper wheel alignment, contributing to a comfortable and safe driving experience. Regular inspections, maintenance, and timely replacements are essential for keeping your ball joints and overall suspension system in top shape.

For more automotive tips and detailed guides, visit Road Momentum, your trusted source for all things Ford F150.